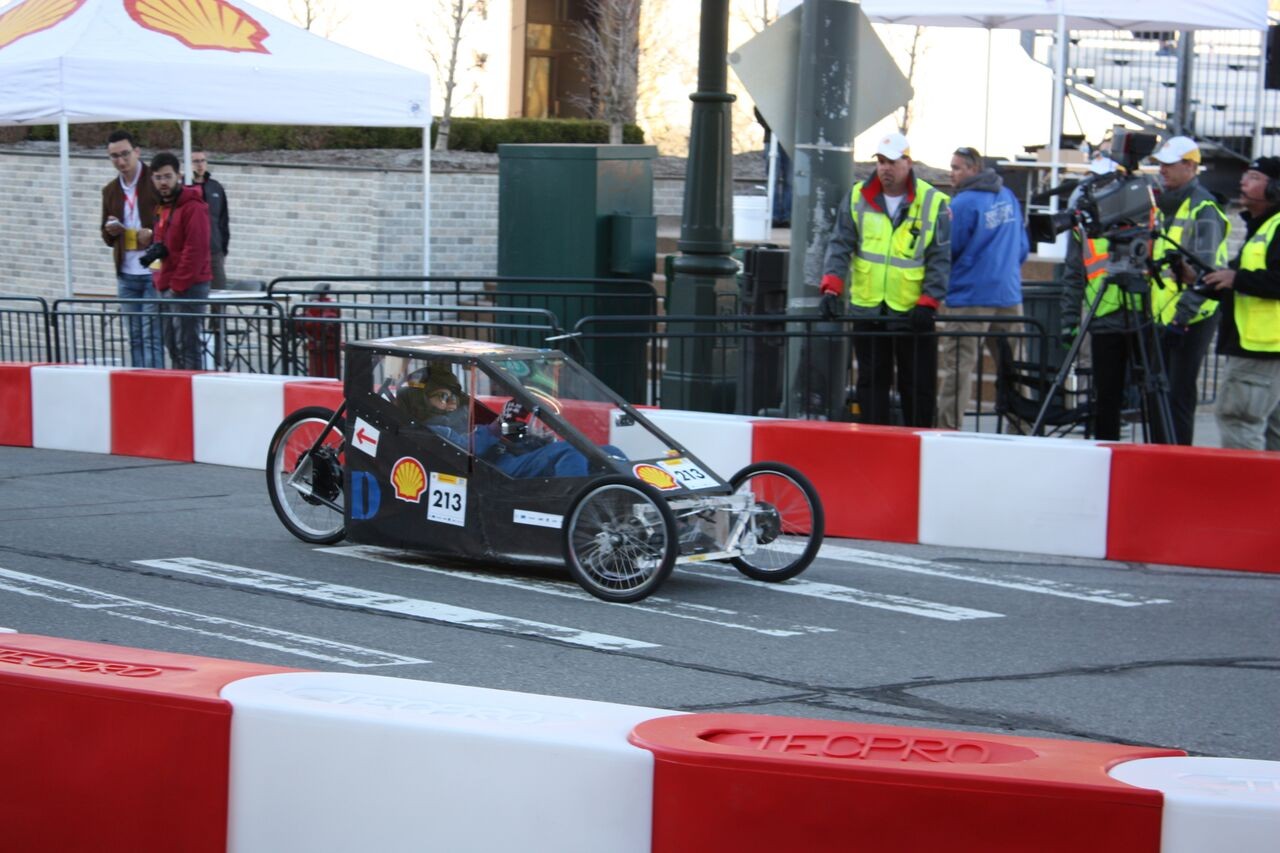

The Hydrogen Fuel Cell car is a student-built project that encompasses the ideas of innovation, technology, and engineering. The car itself is custom-made with a carbon fiber frame and an aluminum base, which helps connect the frame to the three wheels. In the rear, a large bicycle tire attaches to a three phase hub motor. The hub motor utilizes electricity, produced by a Hydrogen Fuel Cell, which is then converted into physical motion. An aluminum bumper connects the two wheels at the front of the car.

Another feature of the Fuel Cell Car is the outer carbon fiber and polycarbonate shell. The “shell” is custom-fitted to the Fuel Cell Car which significantly increases protection for the driver against other cars and projectiles, such as rocks.

Inside the Fuel Cell Car is the seat that embodies the small principles as the outer shell. The custom-made aluminium seat is designed to be ergonomical, yet provides a fire-proof barrier from the electrical system, in case of a rare electrical malfunction.

The actual electrical system consists of three major parts. The most iconic part of the electrical system is a Horizon H-1000 XP Hydrogen Fuel Cell. For more information how a fuel cell works, click here. A second crucial part of the electrical system are the corresponding electronics. The electronics vary in function, but one of the most integral electrical parts is the Crystalyte Motor Controller. The motor controller receives input through a throttle and controls the speed of the motor by varying voltage. The last main component of the electronic system, as referenced before, is the three-phase hub motor that runs on direct current.

2019-2020 Progress:

Brainstorming Ideas for the Front End of The Car

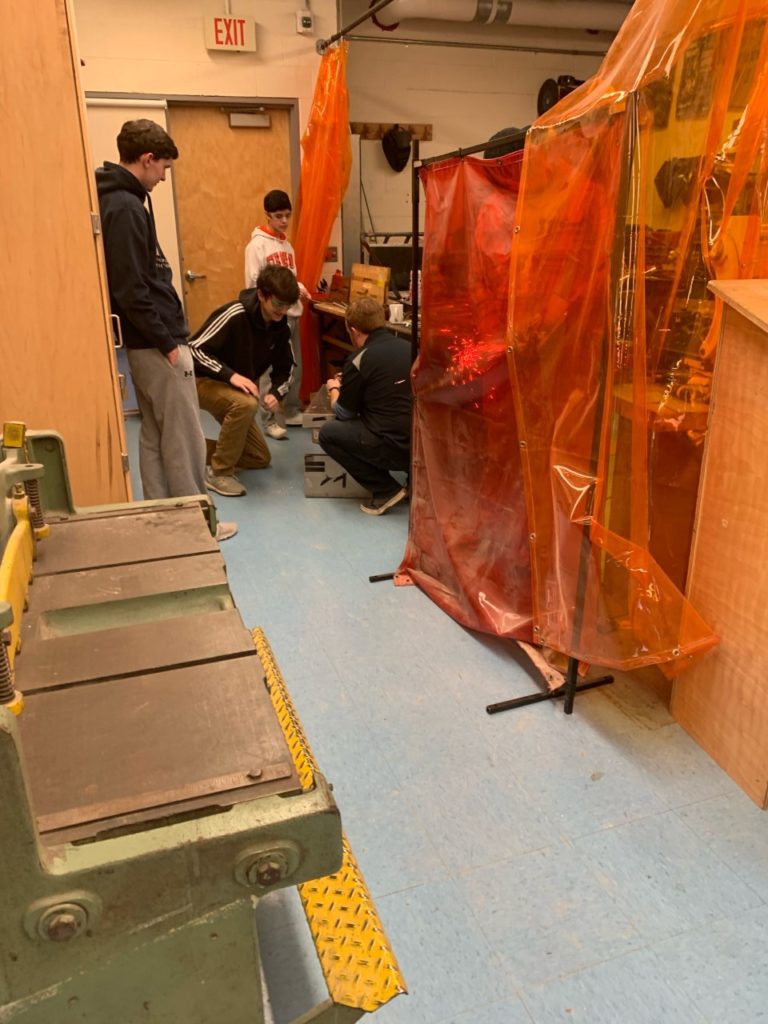

Engineers Learning the Ways of Welding

Car Parts Unassembled: